Among the most urgent challenges is assuring that machines and algorithms learn to anticipate in ways that optimize their interaction with the human workforce. That combination of the digital and physical is where financial and operational advantage lies. JL

Michael Hu reports in MIT Sloan Management Review:

Demands on supply chains are increasing exponentially as companies deliver more personalized products, with faster lead time, at a lower cost. They must develop operational ability to “sense and pivot” in real time. Only by making operations more adaptable, as well as more capable, can companies deliver differentiated value in an increasingly complex, unpredictable world. Enhanced ability to sense and anticipate needs to be complemented with better decisions free of silo-bound decision making where the highest-paid (versus best-informed) person’s opinion prevails.

Unexpected conditions continually disrupt operational performance. Further, demands on supply chains are increasing exponentially as companies vie to deliver more personalized products, with faster lead time, at a lower cost. For these reasons and more, companies must do more than digitize supply chains. They must also develop operational ability to “sense and pivot” in real time. Only by making all your operations more adaptable, as well as more capable, can companies deliver differentiated value in an increasingly complex, demanding, and unpredictable world.

Seeking insights into capabilities to better enable sense and pivot, my colleagues and I recently spent a week at the MIT Media Lab, where A.T. Kearney is a member company and collaboration partner. With its “unique antidisciplinary culture that emboldens unconventional mixing and matching of seemingly disparate research areas,” The Lab is renowned for creating “disruptive technologies that happen at the edges.” That is precisely the kind of thinking operations needs today!

In fact, as we toured The Lab, experienced the solution demos, and chatted with researchers, a clear set of over-arching themes emerged, which we believe these themes can serve as guiding principles for any enterprise looking to transform its future operations and supply chain operating model.

1. Marry Digital with Physical

True transformation of value chains requires a marriage of digital and physical. While it is certainly useful to apply digital native best practices such as scrum or design thinking to physical based problems, (e.g., back-office process design or project development hackathons), this will not be enough. We need truly novel processes and new ways of working that seamlessly blend the digital and physical realms. Perhaps a digital version of the Toyota Andon cord can enable cross-functional leadership to triage S&OP and supply planning issues quicker and faster. In another example, consider re-usable, durable secondary packaging that self-assembles when certain product weight and dimensional constraints are met, thereby reducing the amount of packaging waste while improving product damage and defect waste (see below):

2. Focus on the Human

Our experiences at The Lab also reminded us how important it is to think holistically about the eco-system of users and human participants, rather than just the use-case ROI and underlying technologies. For example, it is not uncommon to think about how reinforcement machine learning algorithms can teach assembly robots to move and operate safely across assembly lines. But maintaining a focus on the human potential calls on us to also explore how to create robots that interact with their human line workers as colleagues by recognizing and reacting to social cues. Instead of focusing on how RPA and machine learning can automate demand forecasting, think about how the system can be designed to enable more frictionless work of downstream human planners, such as voice activated chat-bots for interacting with ERPs and production planning processes. Most companies might benefit significantly from freeing up their imagination in this direction. A customer (internal, external and adjacent) centric approach is key for organizational acceptance to scale new solutions.

3. Expand Peripheral Sensing

Companies typically use the same limited set of data and input signals to sense their market context — whether it’s customer needs, next season’s demand, competitor moves, or supply chain disruptions. Even with the promise of new technologies such as IoT and AI, we gravitate towards the same repository of inputs such as point-of-sale, social media, or voice of customer. More differentiated operational performance will stem from broader and more contextual input data that yields a superior anticipation of future opportunities and issues. Sure, top-down surveys can help get a pulse of the employees in a post-merger integration or zero based transformation effort, but anonymous sentiment assessment of enterprise emails or facial cues in town hall videos can paint a more nuanced and accurate picture (see below):

4. Seek Better Ways to Decide

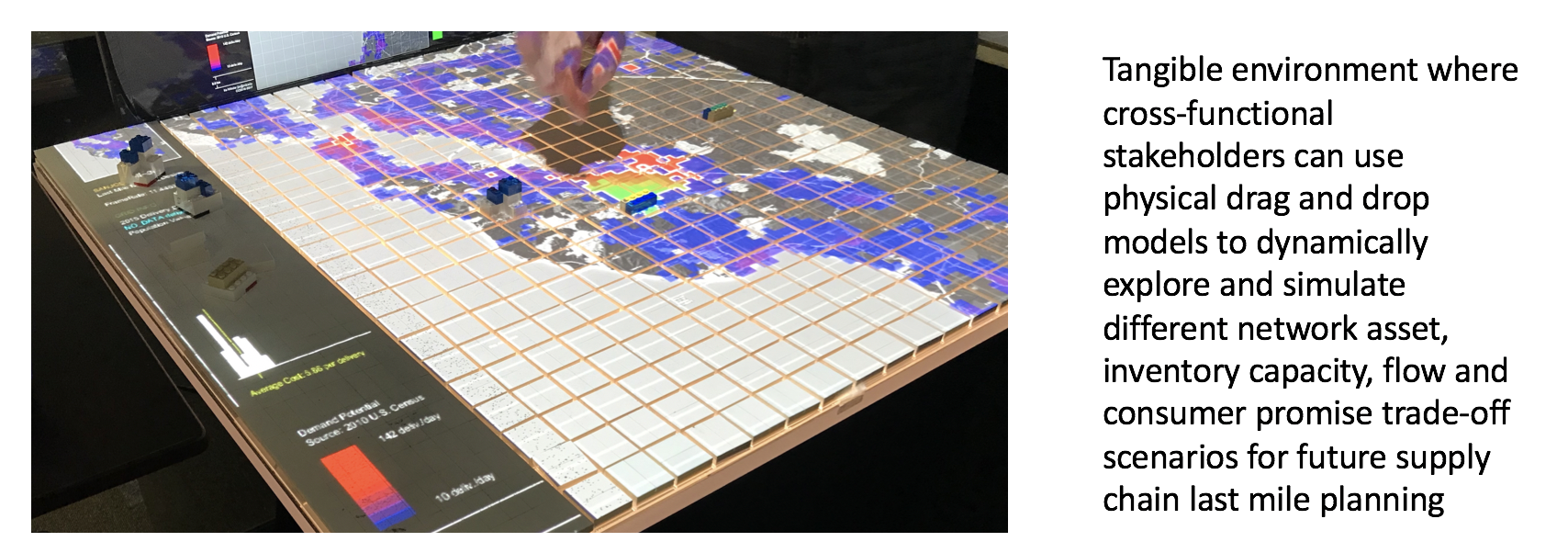

Enhanced ability to sense and anticipate requirements needs to be complemented with better and faster decisions that break free of today’s silo-bound decision making mentality, where the highest-paid (versus best-informed) person’s opinion generally prevails. Companies should consider adopting a simulation-first culture, particularly to stress test significant actions. You might ask, for example: “What does the simulation tell us about the cost of holding more inventory in larger warehouses versus the benefits of tripling our assortment? If I forgo the assortment expansion and use the investment to improve delivery lead time, what would that look like?” Leaders’ intuition still matters, but it must be increasingly fortified by rigorous and objective simulation.

Our time at The MIT Media Lab validated our view that true transformation should not focus merely on technologies, but on possibilities. In any company’s transformation of their future supply chain and operations, turning possibilities into realities should be guided by four imperatives: marry digital with physical, focus on the human, expand peripheral sensing, and seek better ways to decide.

0 comments:

Post a Comment